At CCA Hardchrome, we are constantly striving to provide the best service and products to our customers. That’s why we are excited to announce significant upgrades to our hard chrome plating operation, specifically designed to better serve customers with very large hydraulic cylinder rods, such as those on large mobile cranes.

One of the key upgrades is the installation of new purpose-built, state-of-the-art electroplating tanks, including horizontal plating cells. The centerpiece of which is Australia’s longest 360-degree horizontal-rotation chrome plating tank. The only rotation-plating system of its kind in the country, it is engineered to deliver superior chrome deposit depth and concentricity for rods up to 12 meters in length.

Our new rotation-plating system features a conforming anode system that delivers optimal current density with an ideal anode to cathode ratio, resulting in reduced contaminants and improved adhesion. This ensures even and consistent chrome deposition along the entire length of the rod, achieving chrome deposit depths over 350 microns for rods of extreme length. The result is a hard chrome finish that lasts longer and performs better in the long run, providing our customers with superior quality products.

These upgrades have expanded our capacity and raised the quality of our hard chrome products, allowing us to serve our customers even better.

At CCA Hardchrome, we are dedicated to continuous improvement and investment in cutting-edge technology to meet the evolving needs of our customers. These upgrades have expanded our capacity and raised the quality of our hard chrome products, allowing us to serve our customers even better.

These upgrades to our hard chrome plating operation are a testament to our commitment to excellence, and we look forward to serving our customers with the highest quality hard chrome products for their hydraulic cylinder rod requirements.

Contact us today to learn more about our upgraded hard chrome plating operation and how we can meet your specific needs. We are excited to continue providing top-quality hard chrome products and services to our valued customers at CCA Hardchrome!

CCA Hardchrome recently undertook some independent analysis testing to better understand how our services compare in the market and to get a better understanding of our current workshop capabilities following on from some significant investments in machinery over the last two years.

CCA Hardchrome recently undertook some independent analysis testing to better understand how our services compare in the market and to get a better understanding of our current workshop capabilities following on from some significant investments in machinery over the last two years. In order for hydraulic systems to run smoothly, it is crucial for the chard chrome plating on a cylinder rod to be perfectly finished to precise specifications. There are a number of steps and factors that come into play during the hard chrome plating process to ensure your hydraulic cylinder performs to the required standards.

In order for hydraulic systems to run smoothly, it is crucial for the chard chrome plating on a cylinder rod to be perfectly finished to precise specifications. There are a number of steps and factors that come into play during the hard chrome plating process to ensure your hydraulic cylinder performs to the required standards.

CCA Hardchrome’s latest investment is the addition of a sulphamate nickel plating tank at our Kings Park premises.

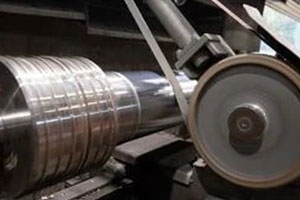

CCA Hardchrome’s latest investment is the addition of a sulphamate nickel plating tank at our Kings Park premises. Our staff at CCA Hardchrome have been anticipating the arrival of a Churchill cylindrical grinding machine – the latest acquisition and addition to our chrome plating facility. This investment allows CCA Hardchrome to expand our capabilities, increase throughput and provide faster turnaround times for our customers.

Our staff at CCA Hardchrome have been anticipating the arrival of a Churchill cylindrical grinding machine – the latest acquisition and addition to our chrome plating facility. This investment allows CCA Hardchrome to expand our capabilities, increase throughput and provide faster turnaround times for our customers.

CCA Hardchrome are pleased to highlight a number of recent successes for the company. We are thankful to all our customers who have continued supporting our mission to deliver chrome plating service excellence.

CCA Hardchrome are pleased to highlight a number of recent successes for the company. We are thankful to all our customers who have continued supporting our mission to deliver chrome plating service excellence. CCA Hardchrome are pleased to announce our recent acquisition by Berendsen Fluid Power. Berendsen Fluid Power are Australia’s leading hydraulics company, servicing and supplying to a hydraulics customers across a diverse range of industries.

CCA Hardchrome are pleased to announce our recent acquisition by Berendsen Fluid Power. Berendsen Fluid Power are Australia’s leading hydraulics company, servicing and supplying to a hydraulics customers across a diverse range of industries.