State of the art facilities configured for efficiency and quality control.

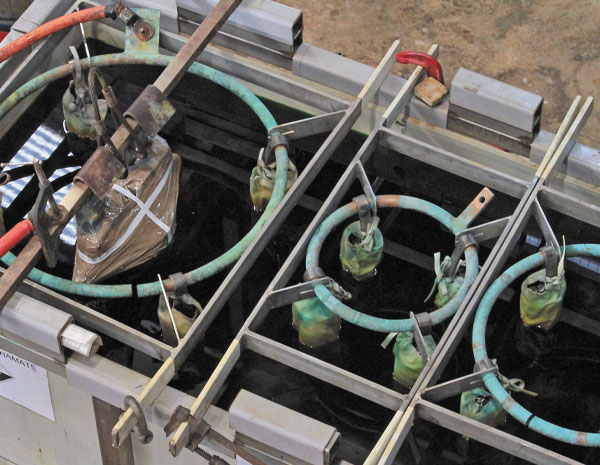

CCA Hardchrome is home to large-scale industrial electroplating facilities set up to primarily serve the needs of the hydraulics industry. As such, the facility possesses everything needed to receive, prepare and treat extremely large components such as cylinder rods used on cranes, earth-moving equipment and other large components. These include purpose-built stripping tanks, large grinding machines, specially configured plating cells and large linishing stations.

Our chrome plating plant is state-of-the-art, maintaining optimal bath chemistry, temperature and current density to produce uniform, dense hard-chrome deposits predictably and reliably. Beyond that, CCA is configured to allow maximum speed and efficiency as jobs make their way from station to station in a systematic manner. This approach reduces lost time while still allowing the experienced CCA team to maintain a vigilant eye on quality at every step in the process.

The standard of the facility is what makes it possible to turn out the consistent high quality upon which the industry depends. With consistent turnaround and high quality results, CCA Hardchrome caters for both large, and smaller scale customers.

Learn more about our about our facilities below, or contact us now at 02 9838 5895 or info@ccahardchrome.com.au.